Reverse engineering is the quickest and most economical method from physical part transfer to 3D computer data. We can produce 2D/3D CAD data of existing physical part including cavity surfaces with our 3D surface scanning machine and accurate 2D optical contour projection instrument.

The Benefits of Reverse Engineering:

1.reduced product development costs.

2.faster product development cycles.

3.Completely duplicates form, fit, function, and interfaces of original part, component, or assembly.

4.high Precision, data accurate to 0.02~0.1 mm.

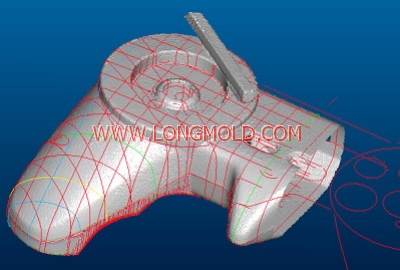

A typical example of reverse engineering:

Step 1: The physical part is scanned using our 3D surface scanning machine to acquire the surface topography. This output is typically a point cloud data set containing millions of points.

Step 2: Convert the point cloud data setto polygonal mesh.

Step 3: Draw or create curves on the mesh using automated tools.

Step 4: Using surface fitting and editing tools, fit NURBS (Non Uniform Rational B-Splines) surfaces to form a watertight surface file. The file can be exported to any CAD, CAM and Rapid Prototyping Software, and can also be converted directly to a parametric Ug or ProE file.

Our full-time design staff and CAD operators can design to your needs.

|